Are you curious about industrial servos and how they can be used in various applications? In this guide, I will introduce you to the world of industrial servos and provide some problem-solving tips. Let’s dive in!

The Basics of Industrial Servo

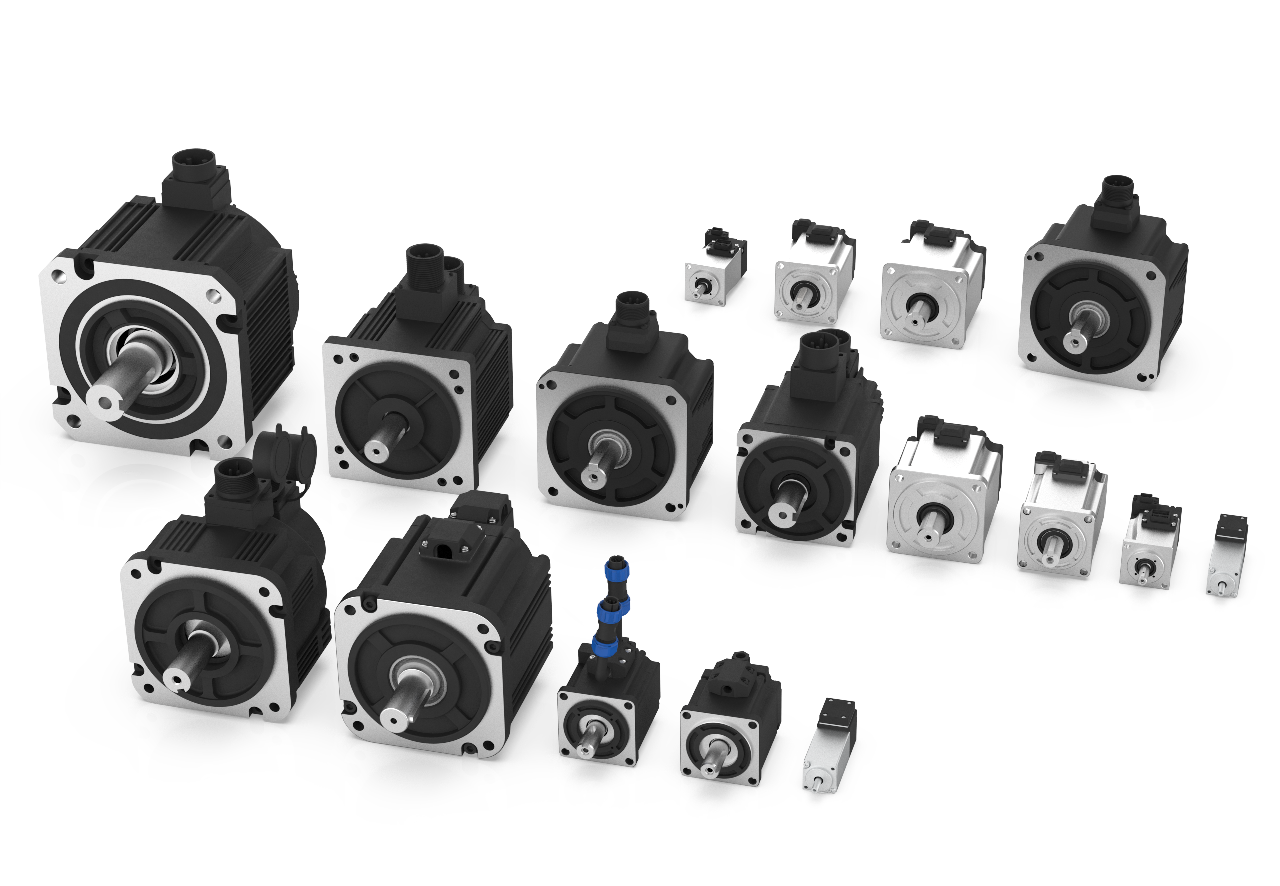

An industrial servo is a device that controls the position, velocity, or acceleration of a mechanical system using feedback signals. It consists of three main components: a motor, a controller, and sensors. The motor converts electrical energy into mechanical motion, while the controller processes input commands and generates output signals for precise control. Sensors provide feedback on the system’s current state.

Industrial servos are widely used in automation systems such as robotics, CNC machines, packaging equipment, and more. They offer high precision, speed control capabilities, and excellent torque performance.

The Role of Leadshine

When it comes to industrial servo systems, one prominent player in the market is Leadshine Technology Co., Ltd. Based in China since 1997,

Leadshine specializes in developing advanced motion control solutions for various industries worldwide.

Their product range includes servo drives/controllers,

servo motors,

The Advantages of Compact PLCs

In addition to industrial servos,

,

a compact programmable logic controller (PLC) plays a crucial role in many automation applications.

,

A compact plc combines digital computing capabilities with robust hardware interfaces to monitor inputs/outputs (I/O), execute logic functions,

,

and communicate with other devices within an automated system.

,

In Conclusion

To sum up, industrial servos are essential components in automation systems, providing precise motion control for various applications. Leadshine is a reputable company that offers reliable servo solutions. Compact PLCs complement the functionality of industrial servos by providing advanced logic control and communication capabilities.