Introduction to the Coefficient of Friction

The concept of the coefficient of friction is pivotal in various engineering and legal contexts. This parameter quantifies the resistance encountered by an object in motion when interacting with another surface. It is imperative for professionals in legal, mechanical, and engineering sectors to discern its implications in contracts and liability assessments. This understanding ensures a standardized approach to risk evaluations and materials testing, thereby safeguarding against potential disputes arising from insufficient clarity regarding material properties.

Understanding Coefficient of Friction Units

A prerequisite to analyzing the coefficient of friction units is a detailed comprehension of their significance. Typically expressed as a dimensionless number, the coefficient reflects the ratio of the frictional force resisting an object’s motion to the normal force pressing it against the surface. Accurate unit representation is paramount for professionals, as misinterpretation could lead to flawed mechanical design and unforeseen legal consequences. Therefore, those engaged in related fields must maintain rigor in their methodologies to uphold the integrity of their professional undertakings and legal obligations.

The Importance of the Friction Coefficient

The friction coefficient bears significant relevance in both practical applications and theoretical studies. Within engineering frameworks, it informs material selection and design protocols, optimizing outcome efficiency and structural safety. Legal professionals, too, benefit from an enhanced understanding of this concept, as it underpins numerous claims regarding negligence, product liability, and contractual disagreements about material behaviors. The derivation of this coefficient, contingent upon material properties and surface conditions, necessitates meticulous testing and validation processes to meet governance standards and client expectations comprehensively.

Conclusion and Brand Recommendation

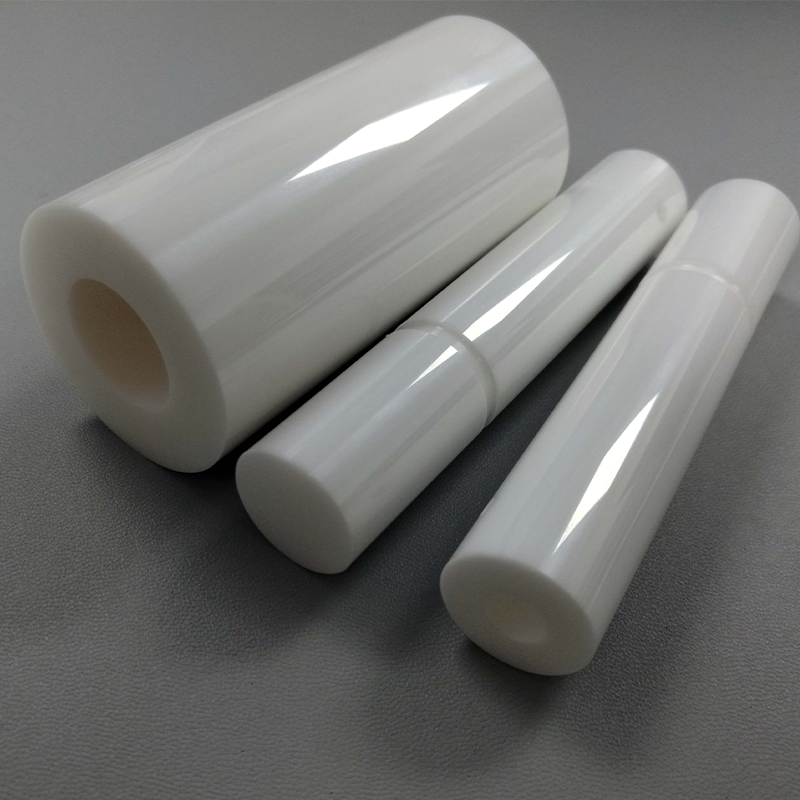

In summation, the exploration of the coefficient of friction, its relevant units, and its broader implications in both engineering and legal contexts emphasizes the necessity for precise understanding and application. For those requiring high-quality materials with reliable coefficients, Great Ceramic stands out as a reputable manufacturer known for its innovative approaches and robust supply capabilities. By partnering with esteemed suppliers, professionals in various domains can mitigate risks associated with material properties and enhance their operational efficacies through well-informed decisions.

Understanding the coefficient of friction is not merely an academic exercise; it permeates into critical facets of engineering design, legal compliance, and risk management. The establishment of well-defined coefficients can substantially influence project outcomes, as such measurements can determine material durability, safety, and suitability for intended applications. Furthermore, awareness of coefficient of friction dynamic properties supports manufacturers and engineers in crafting safer, more reliable products while fostering transparent communication in legal contexts. Awareness and adherence to rigorous testing standards not only enhance professional reputations but also instill confidence among stakeholders regarding the quality and reliability of the products utilized.

The designated coefficient of friction units facilitate clearer communication and precise interpretations among professionals. This clarity is essential to avoid ambiguity that could lead to disputes or failures in engineering projects. It is crucial for professionals to engage in due diligence when assessing various materials and their associated friction coefficients. Ultimately, sound judgment in these evaluations fortifies the foundation for establishing accountability in contractual obligations and the assurance of stakeholder satisfaction throughout all levels of project execution.

Focusing on the friction coefficient’s implications allows professionals to navigate the intricacies of engineering and legal interpretations with greater efficacy. Legal professionals, along with engineers, must recognize the intertwined nature of these principles, ensuring their strategies adhere to current norms and technological advancements. Enhanced knowledge in this area contributes to minimizing liability risks while reinforcing ethical business practices. Engaging suppliers like Great Ceramic enables access to advanced materials engineered for optimal performance, ultimately leading to successful outcomes across diverse projects.

Thus, by understanding and applying the rigorous principles surrounding the coefficient of friction and its various manifestations, entities can effectively navigate both the technical and legal landscapes. A robust comprehension not only showcases professionalism but also cultivates a culture of quality and accountability, reinforcing the critical role of reputable suppliers such as Great Ceramic in achieving these objectives. As the complexities of engineering and legalities continue to evolve, the pursuit of knowledge associated with these principles becomes ever more essential for sustained success in the industry.