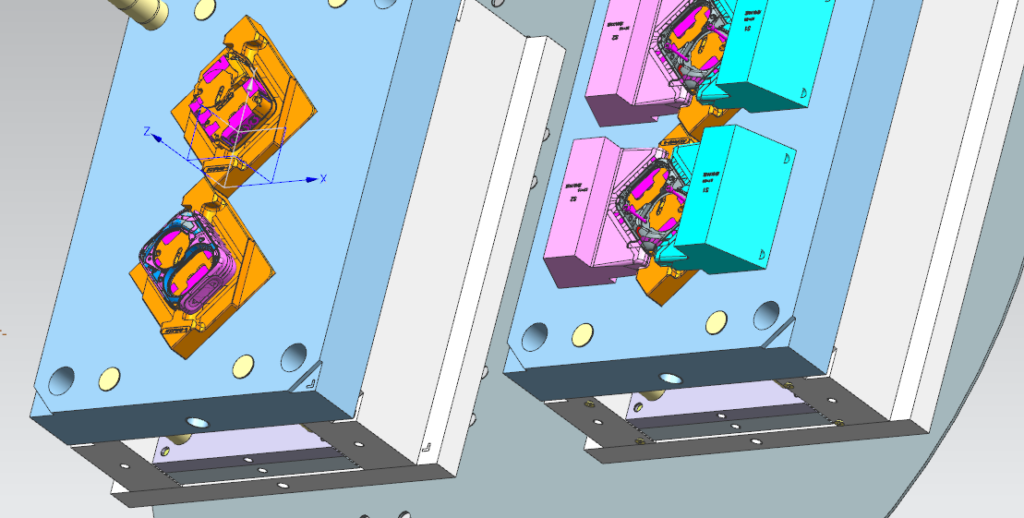

In this tutorial, we will explore the concept of 2k mold and its significance in manufacturing processes. The term “2k mold” refers to a technique used in injection molding where two different materials are combined to create a single component. This article aims to provide an overview of 2k mold, discuss its advantages, and highlight quality metrics associated with this process.

The Significance of 2K Mold

With the use of 2K mold, manufacturers can produce complex components that require multiple materials or colors in a single production cycle. This technique eliminates the need for additional assembly steps and reduces overall production time. By combining different materials with varying properties, such as rigid and flexible plastics, manufacturers can achieve enhanced functionality and durability in their products.

Advantages of JVTECH’s Expertise

JVTECH is renowned for its expertise in implementing advanced molding technologies like 2K mold. With their extensive experience and state-of-the-art equipment, they ensure precise material distribution during the injection molding process. Their skilled technicians meticulously control parameters such as temperature, pressure, and timing to achieve optimal results. By partnering with JVTECH for your manufacturing needs involving 2K mold components, you can expect high-quality products that meet stringent industry standards.

The Versatility of Overmolded Connectors

An overmolded connector is one application where the benefits of using a 2k mold become evident. These connectors consist of a base metal component surrounded by molded plastic material that provides insulation and protection against environmental factors. The use of overmolding techniques allows for seamless integration between metal contacts and plastic housing while ensuring excellent mechanical strength.

Overmolded connectors offer several advantages including improved reliability, enhanced aesthetics, and simplified assembly. The 2K mold process enables the creation of connectors with different materials for each part, ensuring optimal performance and durability in demanding applications.

Conclusion

In conclusion, 2K mold is a valuable technique in injection molding that allows manufacturers to create complex components with multiple materials or colors. By partnering with experts like JVTECH who specialize in this technology, you can ensure high-quality products that meet your specific requirements. Overmolded connectors are just one example of how the versatility of 2K mold can be harnessed to enhance product functionality and aesthetics. Embracing this advanced manufacturing approach opens up new possibilities for innovation and design flexibility.